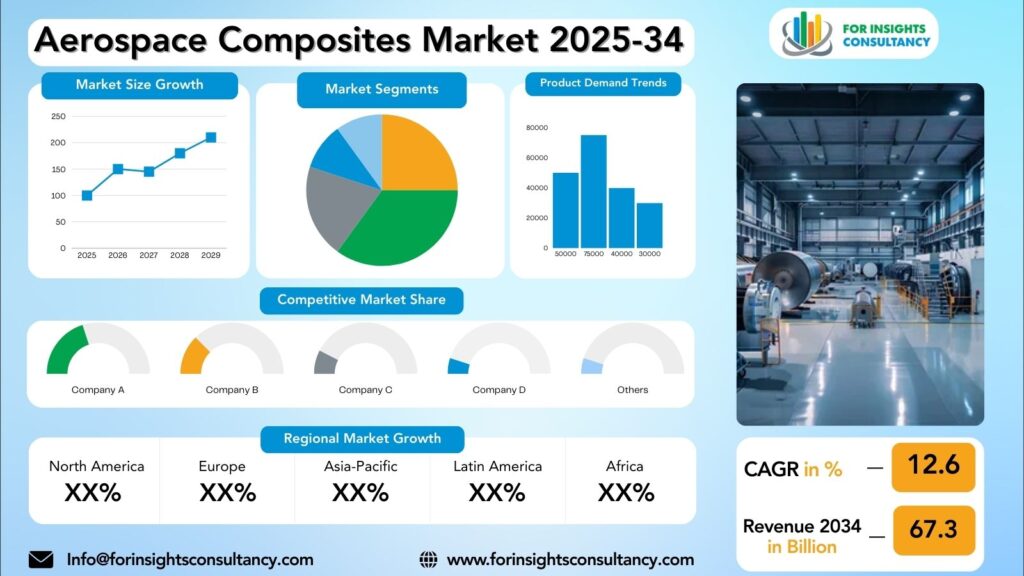

Aerospace Composites Market Research Report by Fiber Type (Carbon Fiber, Glass Fiber, Ceramic Fiber, Aramid Fiber), By Resin Type (Thermoset Composites, Thermoplastic Composites), by Manufacturing Process (Automated Fiber Placement (AFP) / Automated Tape Laying (ATL), Prepreg Layup, Resin Transfer Molding (RTM), Filament Winding, Compression Molding / Injection Molding), by End-Use Industry (Original Equipment Manufacturers (OEMs), Maintenance, Repair, and Overhaul (MRO) / Aftermarket), and Region Global Market Analysis and Forecast, 2025-2034

Aug-2025 Formats | PDF | Category: Chemical | Delivery: 24 to 72 Hours

Aerospace Composites Market is forecast to increase from USD 29.8 Billion in 2025 to USD 67.3 Billion by 2034, at a CAGR of 12.6%.

Aerospace Composites Market: A Comprehensive Overview and Future Developments

The aerospace composites market is a rapidly growing industry that plays a crucial role in the development of lightweight and fuel-efficient aircraft. These composites consist of two or more components, typically a reinforcing fiber like carbon or glass and a matrix material like epoxy resin. These materials are combined to create high-performance and lightweight structures used in various aircraft components, including fuselages, wings, and empennages.

Compared to traditional materials like aluminum and steel, aerospace composites offer benefits such as being lighter, stronger, and more durable, making them ideal for improving fuel efficiency and reducing emissions. They are also corrosion-resistant and have a longer lifespan, resulting in lower maintenance costs. The aerospace composites market is expected to continue growing due to ongoing research and development initiatives and new applications in aircraft design.

Aerospace Composites Market Dynamics

Growth Drivers

The aerospace composites market is experiencing significant growth due to the increasing focus on sustainability and the expansion of the commercial aerospace sector. The industry is focusing on recyclable and environmentally friendly materials, with aerospace composites being increasingly adopted by aircraft manufacturers to enhance their eco-friendly credentials. The expansion of the commercial aerospace sector is also driving demand for lightweight and high-performance materials to meet the stringent requirements of modern aircraft. The shift towards composite-intensive aircraft structures is reshaping the aerospace industry and driving the demand for innovative composite solutions. The rise towards electric and hybrid aircraft is also fueling the growth of the aerospace composites market. These next-generation aircraft require materials with high strength, electrical conductivity, and thermal stability, which aerospace composites can provide. As the aviation industry transitions towards sustainable propulsion technologies, the demand for advanced composites is expected to skyrocket. The aerospace composites market is set to play a pivotal role in shaping the future of the aerospace industry, with endless possibilities on the horizon.

Restraints

The aerospace composites market faces several challenges, including high production costs, lack of standardization in material properties and manufacturing processes, and supply chain disruptions. The high cost of production, including raw materials, specialized equipment, and skilled labor, can be prohibitive for some companies, leading them to opt for traditional materials like aluminum or steel. The lack of standardization in material properties and manufacturing processes can lead to inconsistencies in material quality, performance, and durability, making it difficult for aerospace companies to assess the reliability and safety of composite components.

Supply chain disruptions are another significant challenge in the aerospace composites market. Composite materials are often sourced from global suppliers, and any disruptions can lead to delays in manufacturing and delivery. Natural disasters, political instability, and trade disputes can contribute to supply chain disruptions in the aerospace industry, necessitating careful management of supply chains and developing contingency plans to mitigate the impact of unforeseen events.

Opportunities

The aerospace composites market is experiencing growth due to the increasing demand for lightweight materials in commercial aircraft, military applications, emerging technologies, and renewable energy. Companies are investing in research and development to create cutting-edge composite materials, positioning themselves as industry leaders. Collaboration with other industry players, research institutions, and government agencies can help access new markets and technologies, while strategic partnerships provide access to funding and resources for innovation.

Companies should also focus on sustainability, as regulatory pressure to reduce carbon emissions is increasing. By incorporating recycled materials and reducing waste, companies can appeal to environmentally conscious consumers and attract more customers. The market is also witnessing growth opportunities in the renewable energy sector, with composite materials being used in wind turbine blades and other renewable energy applications. By staying ahead of the curve, companies can capitalize on these growth opportunities and stay ahead of the curve in the aerospace composites market.

Challenges

The aerospace composites market faces several challenges, including the rising cost of raw materials, regulatory compliance and certification, technological advancements and innovation, supply chain disruptions, and environmental sustainability. The industry relies on various composite materials like carbon fiber, fiberglass, and aramid for aircraft components, and the growing demand for these materials has put pressure on manufacturers to find cost-effective ways to source and produce these materials without compromising on quality.

Regulatory compliance and certification are another challenge, as manufacturers must adhere to strict guidelines set forth by regulatory bodies like the Federal Aviation Administration (FAA), which can add time and cost to the production process. Technological advancements and innovations are also crucial, as manufacturers seek ways to improve the performance and durability of composite materials while reducing production costs.

Supply chain disruptions, such as natural disasters, geopolitical events, or pandemics, can significantly impact the aerospace composites market. Manufacturers must diversify their supply chains, build relationships with multiple suppliers, and develop contingency plans to mitigate the impact of potential disruptions.

Environmental sustainability is also a significant concern, as the aerospace industry is under pressure to reduce its carbon footprint and adopt more sustainable practices. Composites offer a lightweight alternative to traditional materials, but their production and disposal can have a significant environmental impact. Manufacturers must work to develop more sustainable production processes and recycling programs to meet the growing demand for eco-friendly aircraft components.

Aerospace Composites Market Top Companies Covered In This Report:

Evaluate The Strategic Positioning And Innovation Pipelines Of Leading Market Companies-From Multinational Enterprises To Disruptive Regional Firms. Understand How Key Players Are Innovating, Expanding, And Capturing Value, And Use Competitive Benchmarks To Plan Your Next Move.

- SGL Carbon

- Spirit AeroSystems

- Materion Corporation

- Lee Aerospace

- General Dynamics Corporation

- Syensqo

- Toray Industries, Inc.

- Mitsubishi Chemical Group Corporation

- Hexcel Corporation

- Teijin Limited

- FDC Composites Inc.

- Avior Produits Intégrés Inc.

- Collins Aerospace

- Aernnova Aerospace S.A

Aerospace Composites Market News

Hexcel

May 28, 2025, Hexcel Presents Lightweight Aerospace Composite Innovations at 55th International Paris Air Show

SGL Carbon

The company announced a major restructuring of its Carbon Fibers business unit in February 2025, including the closure of some unprofitable operations. This move aims to focus on more profitable and differentiated products in its core markets.

Toray Industries

Toray’s news in 2024 and 2025 highlighted its focus on sustainability, including the use of its bio-circular carbon fibers in new sports equipment, which indicates a broader push for sustainable materials across all its markets.

Segmented View of the Industry:

The Aerospace Composites Market Is Mapped Through A Multidimensional Lens-Tracking Shifts Across Product Type, Applications, And Geographic Regions. This Segmented Approach Enables Businesses To Localize Their Growth Plans And Align Offerings With The Most Profitable Demand Centers.

Segmentation by Resin Type

- Thermoset Composites

- Thermoplastic Composites

Segmentation by Fiber Type

- Carbon Fiber

- Glass Fiber

- Ceramic Fiber

- Aramid Fiber

Segmentation by Component

- Solutions

- Services

Segmentation by End-Use Industry

- BFSI (Banking, Financial Services, and Insurance)

- Retail

- Healthcare

- IT and Telecom

- Government and Defense

- Manufacturing

- Other industries

Global Geographic Coverage:

The Report Provides In-Depth Qualitative and Quantitative Data On the Aerospace Composites Market For All Of The Regions And Countries Listed Below:

North America

North America is a leading hub for aerospace innovation, with major players like Boeing and Lockheed Martin leading the way in aircraft manufacturing. The region has a robust aerospace composites market, driven by extensive research and development activities and a strong focus on technological advancements. The United States is a key player in the global aerospace composites market due to its well-established industry and advanced manufacturing capabilities. Canada also plays a significant role in the North American aerospace composites market, with a growing number of aerospace companies investing in research and development of advanced composite materials. The country’s focus on sustainability and environmental consciousness has further fueled the demand for lightweight composites in aircraft manufacturing.

Europe

The aerospace composites market in the UK, Germany, France, Italy, and Spain is dominated by key players like BAE Systems, Rolls-Royce, Airbus, and MT Aerospace AG. The UK’s demand for lightweight and fuel-efficient aircraft is driving the adoption of aerospace composites, and the government’s focus on sustainable aviation is boosting market growth. Germany’s advanced technological capabilities and strong manufacturing base have propelled its growth in the aerospace sector.

France, home to aerospace giants like Airbus and Dassault Aviation, is a key player in the global aerospace industry, with a focus on sustainable aviation and next-generation aircraft development. Italy’s aerospace industry, with companies like Leonardo and Avio Aero, is also a key player in the market. Italy’s expertise in advanced materials and manufacturing technologies has positioned it as a key player in the aerospace composites sector. Spain’s strategic location as a hub for aerospace manufacturing and maintenance contributes to the market’s growth. The aerospace composites market in Spain is set to expand further as the demand for lightweight and durable materials continues to rise.

Asia Pacific

The Asia Pacific region is experiencing rapid growth in the aerospace industry, with countries like China, Japan, and India investing in aviation technology. This has led to a rise in demand for aerospace composites. China, known for its booming aerospace sector, is a key market for aerospace composites due to its ambitious space exploration programs and increasing commercial aircraft production. Major players like COMAC and AVC are leading the way in developing lightweight and durable composites.

Japan, with a strong focus on research and development, is leading the way in developing cutting-edge composite materials for aircraft and spacecraft. Companies like Mitsubishi Heavy Industries and Kawasaki Heavy Industries are leading the way in this space. India, with its growing aerospace industry and ambitious space missions, is also emerging as a promising market for aerospace composites. Companies like Hindustan Aeronautics Limited and Tata Advanced Systems are actively investing in composites technology, positioning India as a key player in the regional market.

Middle East and Africa

The aerospace composites market in the Middle East and Africa regions is experiencing significant growth due to the increasing demand for advanced composites in aircraft manufacturing. The UAE, Saudi Arabia, Qatar, South Africa, and Egypt are all significant players in the market. The UAE’s strategic location has attracted major aerospace companies, leading to collaborations and investment in research and development. Saudi Arabia’s Vision 2030 initiative aims to diversify its economy and strengthen its aerospace industry, offering lucrative opportunities for aerospace composites manufacturers and suppliers.

Qatar is also investing heavily in its aerospace sector, focusing on developing advanced materials like composites. The country’s ambitious infrastructure projects and expanding aviation industry are driving the demand for lightweight and durable composites. South Africa’s well-established aerospace industry and skilled workforce position it as a key player in the regional aerospace composites market. Egypt’s growing aviation sector and government support for aerospace development attract international aerospace companies looking to invest in composites manufacturing and technology. The emerging aerospace composites market in these regions presents exciting prospects for manufacturers, suppliers, and investors.

Reasons to Buy:

- The Research Would Help Top Administration/Policymakers/Professionals/Product Advancements/Sales Managers And Stakeholders In This Market In The Following Ways.

- The Report Provides Aerospace Composites Market Revenues At The Worldwide, Regional, And Country Levels With A Complete Analysis To 2034 Permitting Companies To Analyze Their Market Share And Analyze Projections, And Find New Markets To Aim For.

- To Understand The Most Affecting Driving And Restraining Forces In The Market And Their Impact On The Global Market.

- Major Changes And Assessment In Market Dynamics And Developments.

- The Objective Of The Aerospace Composites Market Report Is To Identify New Business Opportunities Using Quantitative Market Forecasts.

- Formulate Sales And Marketing Strategies By Gaining An Understanding Of Competitors, Their Positioning, And Strengths & Weaknesses.

Faq – What Global Leaders Are Asking

What Is The Growth Prospect For The Aerospace Composites Market By 2034?

Aerospace Composites Market Is Expected To Achieve A Stable Growth Rate With A Compound Annual Growth Rate (Cagr) Of About 12.6% From 2025 Through 2034.

What Is Driving The Growth Of The Aerospace Composites Market?

The aerospace composites market’s growth is driven by the urgent need for aircraft to be more fuel-efficient and environmentally compliant to meet global sustainability goals. This is further fueled by the increasing use of composites in next-generation aircraft and the modernization of military fleets, which demand lighter, stronger, and more durable materials.

Who Are The Key Players In The Aerospace Composites Market, And What Are Their Market Shares?

The Aerospace Composites Market Includes Major Companies Like SGL Carbon, Spirit AeroSystems, Materion Corporation, Lee Aerospace, General Dynamics Corporation, Syensqo, Toray Industries, Inc., Mitsubishi Chemical Group Corporation, Hexcel Corporation, Teijin Limited, FDC Composites Inc., Avior Produits Intégrés Inc., Collins Aerospace, Aernnova Aerospace S.A.

Specific Market Share Data Is Not Publicly Available and Is Typically Provided In Detailed, Proprietary Market Research Reports.

Which Regions Are Leading the Aerospace Composites Market Growth?

North America holds the largest market share, driven by a strong presence of major aircraft manufacturers like Boeing and Lockheed Martin, and extensive R&D funding for advanced materials. The Asia-Pacific region is the fastest-growing market, propelled by increasing air travel demand, rising defense budgets, and new domestic aircraft manufacturing projects in China and India.

Customization: We Can Provide Following Things

1) On Market More Company Profiles (Competitors)

2) Data About Particular Country Or Region

3) We Will Incorporate The Same With No Additional Cost (Post Conducting Feasibility).

Any Requirement Contact Us: Https://Www.Forinsightsconsultancy.Com/Contact-Us/

Table of Contents

For TOC Contact us: https://forinsightsconsultancy.com/contact-us/