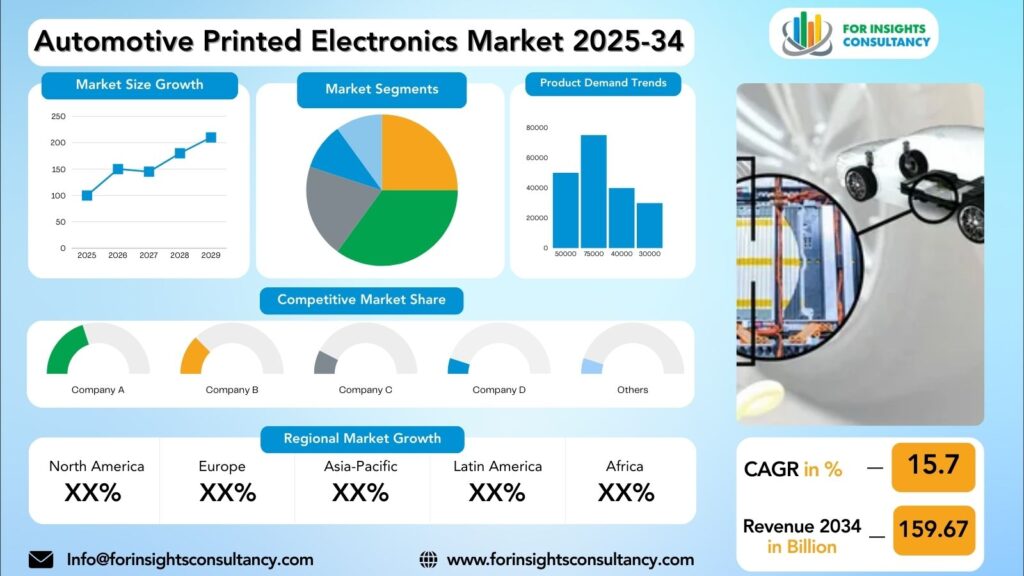

Automotive Printed Electronics Market Research Report by Technology (Screen Printing, Inkjet Printing, Flexography, Gravure Printing, Others (e.g., Aerosol Jet, 3D Printing)), By Vehicle Type (Passenger Vehicles, Light Commercial Vehicles, Heavy-Duty Trucks, Buses and Coaches), by Application (Displays (e.g., infotainment systems, dashboards), Lighting Solutions (e.g., OLED lighting, ambient lighting), Sensors (e.g., pressure, temperature, occupancy sensors), Heaters (e.g., seat heaters, window defoggers), Integrated Antennas, Photovoltaics), and Region Global Market Analysis and Forecast, 2025-2034

Aug-2025 Formats | PDF | Category: Electronics & Semiconductor | Delivery: 24 to 72 Hours

Automotive Printed Electronics Market is forecast to increase from USD 14.5 Billion in 2025 to USD 159.67 Billion by 2034, at a CAGR of 15.7%.

Automotive Printed Electronics Market: A Comprehensive Overview and Future Developments

The automotive printed electronics market is rapidly expanding, transforming the way vehicles are built and operated. It includes advanced dashboard displays and smart sensors in modern automobiles. Key drivers of growth include autonomous vehicles, enhanced connectivity, and environmental sustainability. Autonomous vehicles will require sensors, cameras, and communication systems, while printed antennas and other electronic components will facilitate seamless connectivity between vehicles, infrastructure, and other devices. As vehicles become more connected, there will be a greater demand for advanced communication systems. Printed electronics offer a greener alternative to traditional electronics, making them attractive to environmentally conscious consumers.

Automotive Printed Electronics Market Dynamics

Growth Drivers

The automotive printed electronics market is experiencing growth due to technological advancements, increasing demand for smart features, cost-effectiveness, and efficiency. Manufacturers are creating printed sensors and circuits that can be integrated into various vehicle components, such as touchscreens and lighting systems. This has led to a reshaping of the automotive industry and new opportunities for growth.

The growing demand for smart features in vehicles, such as connected infotainment systems and advanced driver assistance systems, is driving the growth of the automotive printed electronics market. These components enable the integration of sensors, displays, and other electronic components into vehicle design. The cost-effectiveness and efficiency of printed electronics make them an attractive option for the automotive industry.

The lightweight and flexible design of printed electronics also contributes to the growth of the automotive market. By using flexible substrates and thin-film materials, manufacturers can create electronic components that are lightweight, compact, and easy to integrate into vehicle design. This flexibility opens up new possibilities for innovative solutions in automotive electronics, such as curved displays, wearable sensors, and smart textiles.

In conclusion, the automotive printed electronics market is on a trajectory of growth driven by technological advancements, increasing demand for smart features, cost-effectiveness, and efficiency, as well as the lightweight and flexible design of printed electronic components.

Restraints

Automotive printed electronics face several challenges, including durability and reliability, power consumption and efficiency, and scalability and mass production. Traditional electronic components, made from organic materials and thin films, may not be as robust as printed electronics, leading to premature failures and increased maintenance costs. Researchers and engineers are working on developing new manufacturing techniques and materials to improve the durability and reliability of printed electronics. Advanced coatings, encapsulation technologies, and design optimizations can make them more resistant to environmental stresses and mechanical wear, ensuring long-term performance in vehicles.

Power consumption and efficiency are another challenge for automotive printed electronics. As vehicles become more electrified and connected, the demand for energy-efficient electronic systems is higher. Researchers are exploring new materials, designs, and architectures to reduce power consumption while maintaining functionality and performance. Integrating energy-efficient components like organic semiconductors and low-power sensors can improve the efficiency and sustainability of future vehicles.

Scalability and mass production are also significant challenges for automotive printed electronics. Traditional manufacturing processes may not be suitable for high-volume production of printed electronic components. Researchers and manufacturers are developing innovative printing techniques like roll-to-roll printing, screen printing, and inkjet printing to speed up the production process and increase scalability.

Opportunities

The automotive printed electronics market is experiencing growth due to the increasing demand for connected vehicles, which offer advanced infotainment systems, integrated navigation, and seamless connectivity to mobile devices. This demand is driving the development of enhanced safety and security features, such as real-time monitoring of vehicle performance and integration into advanced security systems like keyless entry and engine immobilizers. As consumer demand for safer and more secure vehicles continues to grow, the market for automotive printed electronics is expected to expand.

As the automotive industry focuses on sustainability and environmental responsibility, printed electronics are being used to improve energy efficiency and sustainability. By incorporating lightweight and flexible components into car designs, manufacturers can reduce weight, increase fuel efficiency, and decrease emissions. Printed solar cells can power auxiliary systems and reduce battery drain, leading to greater overall energy savings.

Printed electronics also offer customization options, such as customizable dashboard displays and LED lighting systems, which allow manufacturers to create unique and innovative features in their vehicles. This level of customization enhances the driving experience for consumers and allows them to differentiate their products in a competitive market. As the demand for personalized automotive technology continues to grow, the opportunities for printed electronics are endless.

Challenges

The automotive printed electronics market faces several challenges, including intense competition among players, technological limitations, regulatory compliance, supply chain disruptions, and material shortages. With more companies entering the market, there is increased pressure to innovate rapidly and deliver cost-effective solutions. This can make it difficult for companies to invest in research and development, leading to a slowdown in innovation. To overcome these challenges, companies are focusing on improving production processes and optimizing supply chains.

Technological limitations and performance issues also pose challenges in the automotive printed electronics market. Printed electronic components may not always meet the performance requirements of automotive applications, leading to reliability issues and performance setbacks. To address these limitations, industry players are investing in research and development to improve the performance of printed electronic components.

Regulatory compliance is another significant challenge for companies in the automotive printed electronics market. As vehicles become more connected and autonomous, there is a growing need to meet strict quality standards and regulatory requirements. Companies are working closely with regulatory bodies and investing in quality control measures to demonstrate compliance and build trust with customers.

Supply chain disruptions and material shortages have highlighted the vulnerability of the automotive printed electronics market. To mitigate supply chain risks, companies are diversifying their supplier base and investing in robust supply chain management systems. Building resilient supply chains and maintaining strong relationships with suppliers can minimize the impact of disruptions and ensure continuity in operations.

In conclusion, while the automotive printed electronics market faces its challenges, industry players are proactively addressing them to drive innovation and growth. By investing in research and development, optimizing production processes, and ensuring regulatory compliance, companies can unlock new opportunities in the automotive sector.

Automotive Printed Electronics Market Top Companies Covered In This Report:

Evaluate The Strategic Positioning And Innovation Pipelines Of Leading Market Companies-From Multinational Enterprises To Disruptive Regional Firms. Understand How Key Players Are Innovating, Expanding, And Capturing Value, And Use Competitive Benchmarks To Plan Your Next Move.

- Bosch

- LG Display

- Brückner Maschinenbau GmbH & Co. KG

- Cicor Group

- Henkel AG & Co. KGaA

- Jabil Inc.

- Komura-Tech Co. Ltd.

- Molex LLC

- Nissha Co. Ltd.

- Optomec Inc.

- Tritek Micro Controls Pvt Ltd.

- Witte Technology GmbH

- DuraTech Industries

- Heidelberger Druckmaschinen AG

- Ynvisible Interactive Inc.

- InkTec Co. Ltd

Automotive Printed Electronics Market News

LG Display In February 2025, the company began mass production of its 40-inch Pillar-to-Pillar (P2P) automotive display. This ultra-large, single-panel screen covers the entire dashboard and will be featured in the Afeela, a new electric vehicle from a Sony-Honda joint venture.

29-Feb-2024 At the LOPEC 2024 exhibition, Henkel highlighted its expertise in creating printed self-regulating heaters. Its Positive Temperature Coefficient (PTC) inks enable the creation of uniform, low-voltage heating elements for various automotive applications, such as interior surfaces and seats.

In 2025, Bosch announced new software and hardware for assisted and automated driving, which rely on advanced sensors and electronic components. While not specifically calling out “printed electronics,” these announcements highlight a strategic shift towards vehicle electronics where printed solutions are becoming increasingly relevant.

Segmented View of the Industry:

The Automotive Printed Electronics Market Is Mapped Through A Multidimensional Lens-Tracking Shifts Across Product Type, Applications, And Geographic Regions. This Segmented Approach Enables Businesses To Localize Their Growth Plans And Align Offerings With The Most Profitable Demand Centers.

Segmentation by Technology

- Screen Printing

- Inkjet Printing

- Flexography

- Gravure Printing

- Others (e.g., Aerosol Jet, 3D Printing)

Segmentation by Material

- Conductive Inks

- Substrates

- Semiconductors

- Dielectric & Encapsulation Materials

Segmentation by Vehicle Type

- Passenger Vehicles

- Light Commercial Vehicles

- Heavy-Duty Trucks

- Buses and Coaches

Global Geographic Coverage:

The Report Provides In-Depth Qualitative and Quantitative Data On the Automotive Printed Electronics Market For All Of The Regions And Countries Listed Below:

North America

North America is a significant player in the global automotive printed electronics market due to its major automotive manufacturers, technological advancements, and innovation focus. The United States, with its focus on advanced technologies and the demand for smart vehicles, electric cars, and connected systems, is driving the adoption of printed electronics in the automotive sector. Major players like Ford, General Motors, and Tesla are investing heavily in research and development, while Canada’s focus on sustainability and eco-friendly initiatives is driving the demand for electric vehicles and smart automotive solutions. Canada’s collaboration between public and private sectors is also contributing to significant growth in the automotive printed electronics market. Mexico, a manufacturing hub for the automotive industry, has a booming market for printed electronics components due to its proximity to the United States, favorable trade agreements, and skilled workforce. Mexico’s focus on cost-effective production processes and technological advancements is driving the adoption of printed electronics in vehicles, making it a crucial player in the growth of the automotive printed electronics market in North America.

Europe

Europe is leading in the adoption of printed electronics in the automotive sector, with major players like Germany, France, and Italy leading the way. Germany, a major player in the industry, is investing heavily in integrating printed electronics into vehicles due to the need for lightweight, energy-efficient components and advanced features. France is also embracing printed electronics to improve energy efficiency and reduce carbon emissions. Italian automakers are leveraging printed electronic displays and touch panels to create futuristic interior designs and intuitive control systems, focusing on innovation and design. This trend is expected to drive the growth of the automotive printed electronics market in Europe. Overall, the European market for automotive printed electronics is expected to experience significant growth in the coming years.

Asia Pacific

The automotive industry in the Asia Pacific region has been undergoing a significant shift towards incorporating printed electronics in various components, enhancing functionality and design. Japan, the world’s largest automotive market, has been investing heavily in printed electronics for automotive applications, leading to the development of advanced displays, sensors, and lighting systems. Companies like Panasonic and Denso have been instrumental in driving the growth of printed electronics in the Japanese automotive industry.

China, the world’s largest automotive market, is rapidly adopting printed electronics due to the government’s push towards electric vehicles and smart transportation systems. Companies like BYD and Geely are producing cars with advanced printed electronic components. South Korea, home to electronics giants Samsung and LG, is actively developing printed electronic solutions for automotive applications, such as flexible displays and touch sensors.

India, known for its software industry, is also making strides in the field of printed electronics for automotive use. With a growing demand for connected vehicles and smart technologies, Indian automotive companies are exploring printed electronic solutions for infotainment systems, sensors, and lighting. Companies like Tata and Mahindra are leading the way in integrating these technologies into their vehicles.

The Asia Pacific region is a hub of innovation and growth in the Automotive Printed Electronics Market, with continued rise in the adoption of printed electronics in the automotive industry.

Middle East and Africa

The Middle East, particularly countries like the United Arab Emirates, Saudi Arabia, and Qatar, is a hub of innovation and investment in various sectors, including automotive electronics. These nations are investing heavily in research and development to drive innovation, particularly in the automotive printed electronics market. The region’s focus on sustainability and energy efficiency is driving the growth of printed electronics, offering solutions for lightweighting vehicles, reducing energy consumption, and enhancing performance. The presence of leading automotive manufacturers and suppliers in the Middle East creates a conducive environment for the adoption of printed electronics technology.

Africa presents unique challenges and opportunities for growth in the automotive industry. With a growing population and urbanization, there is a growing demand for affordable and sustainable transportation solutions. Printed electronics offer a cost-effective alternative to traditional electronic components, making them increasingly attractive to African manufacturers. Countries like Nigeria, South Africa, and Kenya are emerging as key players in the automotive printed electronics market in Africa. They have fostered innovation and entrepreneurship in the automotive sector, creating a conducive ecosystem for the development of printed electronics technology.

Printed electronics in Africa can address infrastructure and logistics challenges, making them ideal for local production and assembly. This localization of printed electronics manufacturing can drive economic growth and job creation in the automotive sector.

Reasons to Buy:

- The Research Would Help Top Administration/Policymakers/Professionals/Product Advancements/Sales Managers And Stakeholders In This Market In The Following Ways.

- The Report Provides Automotive Printed Electronics Market Revenues At The Worldwide, Regional, And Country Levels With A Complete Analysis To 2034 Permitting Companies To Analyze Their Market Share And Analyze Projections, And Find New Markets To Aim For.

- To Understand The Most Affecting Driving And Restraining Forces In The Market And Their Impact On The Global Market.

- Major Changes And Assessment In Market Dynamics And Developments.

- The Objective Of The Automotive Printed Electronics Market Report Is To Identify New Business Opportunities Using Quantitative Market Forecasts.

- Formulate Sales And Marketing Strategies By Gaining An Understanding Of Competitors, Their Positioning, And Strengths & Weaknesses.

Faq – What Global Leaders Are Asking

What Is The Growth Prospect For The Automotive Printed Electronics Market By 2034?

Automotive Printed Electronics Market Is Expected To Achieve A Stable Growth Rate With A Compound Annual Growth Rate (Cagr) Of About 15.7% From 2025 Through 2034.

What Is Driving The Growth Of The Automotive Printed Electronics Market?

The market’s growth is driven by the rapid shift to electric and software-defined vehicles, which require lightweight, flexible, and integrated electronic components. This is further fueled by rising consumer demand for advanced in-cabin features like seamless, curved displays, and interactive smart surfaces.

Who Are The Key Players In The Automotive Printed Electronics Market, And What Are Their Market Shares?

The Automotive Printed Electronics Market Includes Major Companies Like Bosch, LG Display, Brückner Maschinenbau GmbH & Co. KG, Cicor Group, Henkel AG & Co. KGaA, Jabil Inc., Komura-Tech Co. Ltd., Molex LLC, Nissha Co. Ltd., Optomec Inc., Tritek Micro Controls Pvt Ltd., Witte Technology GmbH, DuraTech Industries, Heidelberger Druckmaschinen AG, Ynvisible Interactive Inc., InkTec Co. Ltd.

Specific Market Share Data Is Not Publicly Available and Is Typically Provided In Detailed, Proprietary Market Research Reports.

Which Regions Are Leading the Automotive Printed Electronics Market Growth?

The Asia-Pacific region is the clear leader in the automotive printed electronics market, driven by its position as a global manufacturing hub and the rapid adoption of electric and smart vehicles in countries like China and South Korea. North America and Europe are also significant markets, with growth fueled by strong R&D, technological innovation, and a focus on premium vehicle features.

Customization: We Can Provide Following Things

1) On Market More Company Profiles (Competitors)

2) Data About Particular Country Or Region

3) We Will Incorporate The Same With No Additional Cost (Post Conducting Feasibility).

Any Requirement Contact Us: Https://Www.Forinsightsconsultancy.Com/Contact-Us/

Table of Contents

For TOC Contact us: https://forinsightsconsultancy.com/contact-us/