Wire Harness Market Research Report by Vehicle Type (Passenger Cars, Commercial Vehicles, Two-Wheelers, Off-the-Road (OTR) Vehicles), by Application (Body & Lighting Harness, Chassis Harness, Engine Harness, HVAC (Heating, Ventilation, and Air Conditioning) Harness, Sensors & Infotainment Harness), and, by Conductor Material (Copper, Aluminum, Optical Fiber), by Propulsion Type & Voltage (Internal Combustion Engine (ICE) Vehicles, Electric Vehicles (EVs), Hybrid Vehicles), by End-User (Automotive, Aerospace & Defense, Industrial Machinery, Consumer Electronics), And by Region- Global Forecast to 2034

Aug-2025 Formats | PDF | Category: Electronics & Semiconductor | Delivery: 24 to 72 Hours

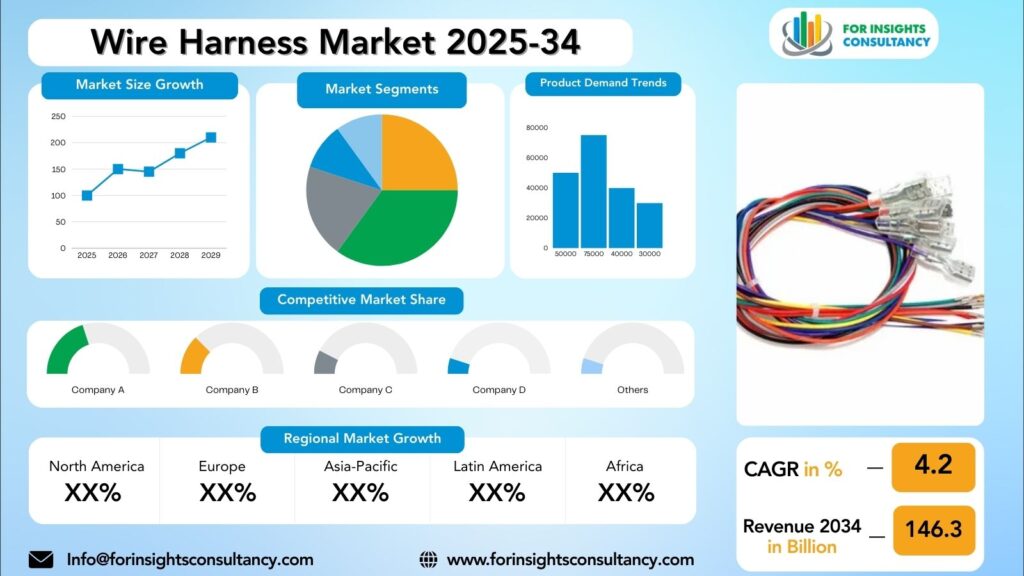

Wire Harness Market is forecast to increase from USD 102.8 billion in 2025 to USD 146.3 billion by 2034, at a CAGR of 4.2%.

Wire Harness Market: A Comprehensive Overview

A wire harness, also known as a cable harness or wiring assembly, is a group of wires and cables that are brought together to carry electricity or signals. Wire harnesses are ubiquitous, used in countless devices, vehicles and machines, which provide a solid and organized connection for individual elements.

Miniaturization of components: The trend of making devices smaller and in compact form factors increases the need for lighter and compact wire harness assemblies.

Smarts coming into play: The implementation of IoT, AI and smart technologies has been used in wire harnesses, namely smart wire harness being capable of offering remote monitoring and adjunction over various functionality.

Sustainable materials are becoming more infinite: Primarily manufacturers are looking for alternative or environment friendly materials to make wire harness, in adding to environmental stress and compliance issues.

The wire harness market is expected to grow a lot over the next few years as more electric vehicles are being developed and adopted, the aerospace and defense industries continue to grow, and the direction of smart technologies becomes more common. Manufacturers will likely devote resources to research and development to create more advanced wire harness solutions that meet the evolving needs of the industries that utilize them.

Wire Harness Market Dynamics

Growth Drivers

The automotive industry is a huge element of the wire harnesses market and seeing growth in wire harnesses, due to the increase in electric vehicles and new technology with new advanced electronics, which continues to expand the need for more intricate and customized wiring from components into an assembly.

Also, continued innovation in electronics and aerospace’ sectors continues to generate a need for relatively complex wire harness systems maxing out high-speed data retention and power.

The industrial automation sector is also seeing increased demand for wire harnesses to improve manufacturing processes and efficiencies.

Restraint

One of the major constraints affecting the wire harness market is the increasing costs of raw materials. Manufacturers are challenged by the rise in prices of copper, plastics, and other raw materials to keep pricing in line with the market. This can lead to shrinking profit margins and burden companies with finding ways to produce a wire harness most economically.

In addition, the complexity of today’s vehicles and machines can challenge wire harness manufacturers. There is a high demand for advanced products that contain electric components, as well as sensors and connectivity options. This complexity will add to the design and manufacturing of wire harnesses, which can lead to longer production times, increased costs, and ultimately questions about quality control.

Opportunity

While there are challenges, the wire harness sector does offer some important opportunities. Possibly the greatest opportunity is the increase in the use of electric vehicles. Around the world, governments are encouraging the uptake of electric vehicles in order to regulate carbon emissions. The demand for wire harnesses for electric components is expected to increase immensely due to this transition. This presents tremendous revenue potential for wire harness manufacturers to grow their product offerings and service this segment.

Furthermore, advances in technology, including automation, artificial intelligence, and robotics, provide another opportunity for wire harness manufacturers to enhance efficiency and productivity. Investing in automated production facilities processes and other innovative technologies can help manufacturers improve production cycles of wire harnesses, speed up production rates of wire harnesses while improving quality.

Challenges

Supply Chain Disruptions: The global supply chain disruptions caused by the COVID-19 pandemic have impacted the availability of raw materials and components, resulting in delays in production and delivery.

Quality Control Issues: It can be difficult to ensure the quality and reliability of wire harnesses, especially given the complexity of modern systems and variety in testing and validation.

Increasing Competition: The wire harness market is very competitive with many players competing for share by innovating better solutions and providing competitively priced products.

Wire Harness Market Top Companies Covered In This Report:

Evaluate The Strategic Positioning And Innovation Pipelines Of Leading Market Companies-From Multinational Enterprises To Disruptive Regional Firms. Understand How Key Players Are Innovating, Expanding, And Capturing Value, And Use Competitive Benchmarks To Plan Your Next Move.

- BorgWarner, Inc.

- Coroplast Group (WeWire)

- AME Systems

- Aptiv Plc

- Draexlmaier

- Elcom International

- Fujikura Ltd.

- Furukawa Electric Co. Ltd.

- Kromberg & Schubert

- Kunshan Huguang Auto Harness Co. Ltd.

Wire Harness Market News

January 22, 2025 Aptiv Announces Intention to Separate Its Electrical Distribution Systems Business

Aptiv PLC (the “Company”), a global technology company enabling a more safe, green and connected future, today announced that its Board of Directors has unanimously approved a plan to separate its Electrical Distribution Systems business (“EDS” or the “EDS business”) from Aptiv, creating two independent companies, each optimally positioned to serve their customers and create value for their shareholders.

15th May 2025 Elcom-How Wiring Harnesses Improve Efficiency in Electrical Systems

A wire harness, alternatively known as a cable harness or wiring harness, offered by wiring harness manufacturers in India constitutes a structured assembly of wires, cables, and connectors designed to transmit signals or electrical power across diverse applications.

May 9, 2024 End of production of Fujikura Automotive MLD SRL

Fujikura Ltd. (Director, President and CEO: Naoki Okada) has decided to end production of automotive Wire harness at Fujikura Automotive MLD SRL. Fujikura Automotive MLD SRL was established and began operations in 2016 as a production base for Wire harness for customer in Eastern Europe. Due to a change in the model lineup of customer’ production vehicles, production of our ordered models will be discontinued. As a result, we have decided to end production of automotive Wire harness at Fujikura Automotive MLD SRL.

Aug 31, 2023 BorgWarner to integrate STMicroelectronics’ Silicon-Carbide Technology in Viper Power Module for Volvo Cars’ Next-Generation Electric Vehicles

Segmented View of the Industry:

The Wire Harness Market Is Mapped Through A Multidimensional Lens-Tracking Shifts Across Product Type, Applications, And Geographic Regions. This Segmented Approach Enables Businesses To Localize Their Growth Plans And Align Offerings With The Most Profitable Demand Centers.

Segmentation By Vehicle Type

- Passenger Cars

- Commercial Vehicles

- Two-Wheelers

- Off-the-Road (OTR) Vehicles

Segmentation By Application

- Body & Lighting Harness

- Chassis Harness

- Engine Harness

- HVAC (Heating, Ventilation, and Air Conditioning) Harness

- Sensors & Infotainment Harness

Segmentation by Conductor Material

- Copper

- Aluminum

- Optical Fiber

Segmentation by Propulsion Type & Voltage

- Internal Combustion Engine (ICE) Vehicles

- Electric Vehicles (EVs)

- Hybrid Vehicles

Segmentation byEnd-User

- Automotive

- Aerospace & Defense

- Industrial Machinery

- Consumer Electronics

Global Geographic Coverage:

The Report Provides In-Depth Qualitative and Quantitative Data On The Wire Harness Market For All Of The Regions And Countries Listed Below:

North America

In North America, the wire harness market involves key players in which the United States and Canada lead with innovations in technology. The United States and Canada have a large number of automotive manufacturers and electrical equipment suppliers. Therefore automotive and electrical manufacturers consume wire harnesses and equipment that relies on them.

In the automotive industry, U.S. wire harness consumption is shown through electrical automotive sector businesses as there is increasing demand for electric vehicles, and development of autonomous driving vehicles. Aeronautics also contributes to the growth of the market in developing next-generation aircraft and aerospace drones.

Canada has a number of wire harness manufacturers in almost all the other major industries which allows demand across several sectors. Continued advancements in sustainable energy solutions, and emphasis given to developing renewable technologies to support multi-industry workforce across Canada further leads to increased wire harness consumption in the provincial and national markets.

Europe

Germany

As a leading country in the European automotive sector, Germany is a critical market for wire harness manufacturers and suppliers. Some of the world’s largest automobile manufacturers, including Volkswagen, BMW, and Mercedes-Benz, are based in Germany, where development work is increasingly focusing on new and innovative technologies. As such, German companies are in need of more advanced wire harness solutions to support the requirements of modern vehicles.

France

France has long been known for its prowess in automobile production, making it another important market for wire harness manufacturers. Its vast expertise and demand remain in luxury vehicles such as those produced by Renault and Peugeot, which must remain ahead of the curve when it comes to product innovations and quality, not to mention custom wire harnesses for new product offerings. French automotive manufacturers have also made a great deal of investment in electric and hybrid technologies, which is driving demand for more custom wire harness solutions.

United Kingdom

Despite Brexit, the United Kingdom remains a significant part of the European wire harness market. The United Kingdom is also home to many automotive manufacturers, including Jaguar Land Rover and Aston Martin, both of whom produce luxury vehicles. Due to the push from their government regarding the transition to electric vehicles, there is increasing demand for wire harnesses that will provide the functionality required for the next generation of clean energy automobiles.

Asia Pacific

China

China’s rapid development of the automotive and electronics sector has made it the largest regional market for wire harness in Asia. China is home to many large automotive OEM’s and electric vehicles are emerging rapidly, driving demand for wire harness. In the years ahead, wire harness demand will steadily increase.

Japan

Japan is well-known for being composed of the most advanced technology-based companies with products focusing on both automotive and electronics space. Manufacturing in Japan has been built on a foundation of strong techniques with rigorous quality control. In the days and years ahead, Japan’s focus on automation and the transition to electric vehicles will drive increasing wire harness demand.

South Korea

South Korea has numerous multinational electronics companies and a growing automotive sector. Korea’s specialty in semiconductor manufacturing and robust technological development will help make it a key wire harness market in the years ahead. Electric vehicles and smart devices will continue to drive demand for wire harness in Korea.

Middle East and Africa

United Arab Emirates (UAE)

Over the past years, the UAE is slated to be an important market for wire harness manufacturers in active response and no small part because of the drastic industrialization and overall infrastructure development projects. The automotive sector in the UAE is clearly booming and is likely to be a active driver for demand for wire harness solutions, if for no other reason than, luxury vehicle manufacturers are requiring wire harnesses for their custom designed needs.

Saudi Arabia

Saudi Arabia is another key market in the Middle East region, and the focus is towards increasing that country’s automotive manufacturing sector. Saudi Arabia’s focus to diversify its economy away from oil was a major driver behind additional investments into the automotive marketplace which, in and of itself will provide more demand for wire harnesses as a supplier component.

Turkey

Turkey is establishing a role for itself as a regional automotive manufacturing center to encourage OEMs and/or suppliers to set up manufacturing facilities in the country. Due to the growing automotive industry, Turkey is producing demand for wire harnesses; however, the focus seems to be on developing vehicle safety and performance.

South Africa:

The automotive industry in South Africa continues to grow steadily, benefiting from government incentives and infrastructural development projects. With government efforts focusing on electric vehicle and clean energy solutions, market demand for wire harness innovation spurring the transition to green mobility is growing.

Nigeria:

Nigeria has quickly become a key market for wire harness manufacturers as the country looks towards expanding its automotive manufacturing capacity and reducing reliance on imports. The increased focus on local production and assembly for vehicles is also providing opportunities for wire harness suppliers to enter the market.

Reasons to Buy:

- The Research Would Help Top Administration/Policymakers/Professionals/Product Advancements/Sales Managers And Stakeholders In This Market In The Following Ways.

- The Report Provides Wire Harness Market Revenues At The Worldwide, Regional, And Country Levels With A Complete Analysis To 2034 Permitting Companies To Analyze Their Market Share And Analyze Projections, And Find New Markets To Aim For.

- To Understand The Most Affecting Driving And Restraining Forces In The Market And Their Impact On The Global Market.

- Major Changes And Assessment In Market Dynamics And Developments.

- The Objective Of The Wire Harness Market Report Is To Identify New Business Opportunities Using Quantitative Market Forecasts.

- Formulate Sales And Marketing Strategies By Gaining An Understanding Of Competitors, Their Positioning, And Strengths & Weaknesses.

Faq – What Global Leaders Are Asking

What Is The Growth Prospect For The Wire Harness Market By 2034?

Wire Harness Market Is Expected To Achieve A Stable Growth Rate With A Compound Annual Growth Rate (Cagr) Of About 4.2% From 2025 Through 2034.

What Is Driving The Growth Of The Wire Harness Market?

The wire harness market’s growth is primarily driven by the increasing production of vehicles, especially the rising adoption of electric and hybrid cars. The growing complexity of vehicle electronics, including ADAS and infotainment systems, necessitates more intricate and advanced wiring systems.

Who Are The Key Players In The Wire Harness Market, And What Are Their Market Shares?

The Wire Harness Market Includes Major Companies Like BorgWarner, Inc., Coroplast Group (WeWire), AME Systems, Aptiv Plc, Draexlmaier, Elcom International, Fujikura Ltd., Furukawa Electric Co. Ltd., Kromberg & Schubert, Kunshan Huguang Auto Harness Co. Ltd.

Specific Market Share Data Is Not Publicly Available And Is Typically Provided In Detailed, Proprietary Market Research Reports.

Which Regions Are Leading The Wire Harness Market Growth?

The Asia-Pacific region is the clear leader in the wire harness market, driven by its large-scale automotive manufacturing base and the rapid adoption of electric vehicles. North America and Europe are also significant markets, with growth fueled by the replacement of aging infrastructure and the push for advanced vehicle technologies.

Customization: We Can Provide Following Things

1) On Market More Company Profiles (Competitors)

2) Data About Particular Country Or Region

3) We Will Incorporate The Same With No Additional Cost (Post Conducting Feasibility).

Any Requirement Contact Us: Https://Www.Forinsightsconsultancy.Com/Contact-Us/

Table of Contents

For TOC Contact us: https://forinsightsconsultancy.com/contact-us/